Cabinet Coolers

Stop electronic control downtime due to heat, dirt and moisture! Cabinet Coolers maintain NEMA 4, 4X and 12 integrity. All Cabinet Cooler are UL and CE compliant!

What is an EXAIR Cabinet Cooler System?

A low cost, reliable way to cool and purge electronic control panels. EXAIR Cabinet Coolers incorporate a Vortex Tube to produce cold air from compressed air - with No Moving Parts. The compact Cabinet Cooler can be installed in minutes through a standard electrical knockout. NEMA 12, 4 and 4X (IP54 and IP66) Cabinet Coolers that match the NEMA rating of the enclosure are available in many cooling capacities for large and small control panels.

Why EXAIR Cabinet Cooler Systems?

The Vortex Tubes incorporated in the EXAIR Cabinet Coolers are construction of stainless steel. The wear, corrosion and oxidation resistance of stainless steel assures long life and maintenance free operation. All Cabinet Coolers are UL Listed and CE compliant.

How The Cabinet Cooler Works?

Compressed air enters the vortex tube powered Cabinet Cooler and is converted into two streams, one hot and one cold. Hot air from the Vortex Tube is muffled and exhausted through the vortex tube exhaust. The cold air is discharged into the control cabinet through the cold air distribution kit. The displaced hot air in the cabinet rises and exhausts to atmosphere through the cabinet air exhaust at a slight positive pressure. Thus, the control cabinet is both cooled and purged with cool, clean air. Outside air is never allowed to enter the control panel.

Selecting The Right Model - Know Your System Options

Each different NEMA rated Cabinet Cooler system is available with a Thermostat Control or as a Continuous Operation System. Each of these systems will include a water-dirt Filter Separator to prevent water condensate and dirt from entering your enclosure and Cold Air Distribution Kit used to direct the air for circulation or on to hot spots. EXAIR also manufactures Cabinet Cooler Systems for difficult environments, Non-Hazardous purge environments and Type 316SS material coolers for highly corrosive environments.

Click here TO SELECT THE RIGHT CABINET COOLER MODEL FOR YOUR APPLICATION (THE RESULT MAY NOT BE ACCURATE, FURTHER CONSULTATION IS REQUIRED)

NEMA Rating

The first step to solving your overheating problem is to identify the NEMA integrity your enclosure will require. At below is an explanation to help you determine which NEMA integrity Cabinet Cooler System we should ship to you.

- NEMA 12 (IP54) Cabinet Coolers (dust-tight, oil-tight) are ideal for general industrial environments where no liquids or corrosives are present.

- NEMA 4 (IP66) Cabinet Coolers (dust-tight, oil-tight, splash resistant, indoor/outdoor service) incorporate a low pressure relief valve for both Vortex Tube and cabinet air exhaust. This valve closes and seals when the cooler is not operating to maintain the integrity of a NEMA 4 enclosure.

- NEMA 4X (IP66) Cabinet Coolers offer the same protection as NEMA 4 but are contructed of stainless steel for food service and corrosion environments.

Thermostat Control

The thermostat control systems are the most efficient way to operate a Cabinet Cooler. They save air by activating the cooler only when internal temperature approach critical levels. Thermostat Controlled Cooler Systems are the best option when experiencing fluctuating heat loads caused by environment or seasonal changes. The standard thermostat control systems include an adjustable thermostat factory set at 95ºF (35ºC).

ETC Electronic Temperature Control

EXAIR's digital ETC (Electronic Temperature Control) provides precise temperature control for your electrical enclosure. It can accurately maintain a constant temperature that is slightly under the maximum rating of the electronics, permitting just enough cooling for the electronics without going so cold as to waste compressed air. The LED readout of the ETC display the internal temperature of the elctrical enclosure (ºF or ºC) that is constantly being monitored by a quick response thermocouple. The control activates the solenoid valve (included) when the temperature setting is exceeded. The polycarbonate plastic enclosure of the ETC is suitable for NEMA 12, 4 and 4X environments. (Cabinet Cooler not included).

Special Cabinet Coolers

EXAIR manufactures special NEMA 12 (IP54), 4 (IP66) and 4X (IP66) Cabinet Coolers suited to specific environmental requirements:

High Temperature Cabinet Coolers

For ambient temperatures of 125 to 200ºF (52º to 93ºC) are available. Internal components can withstand high temperatures (like those near furnaces, ovens, etc).

Non-Hazardous Purge Cabinet Cooler Systems

For dirty areas where contaminants might normally pass through small holes or conduits. Under normal conditions, the NHP Cabinet Cooler Systems provide a slight positive pressure in the enclosure by passing 1 SCFM (28 SLPM) of air through the cooler, when the solenoid valve is in the closed position. When the thermostat detects high temperature, it energizes the solenoid valve to pass full line pressure and volume of compressed air to the Cabinet Cooler, giving it full cooling capability.

Type 316 Stainless Steel NEMA 4X Cabinet Coolers

Suitable for food service, pharmaceutical, harsh and corrosive environments and other applications where 316SS is preferred. Capacity from 275 to 5,600 Btu/hr (69 to 1,411 Kcal/hr) are available.

HEAT CAN STOP YOUR MACHINES!!

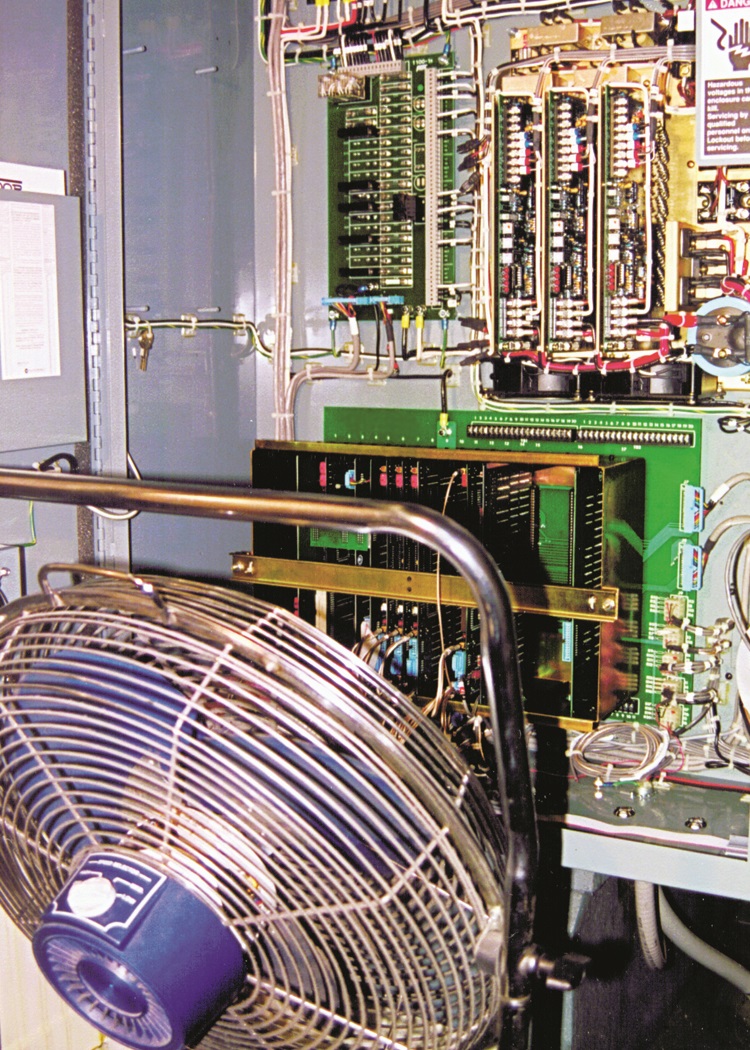

It happens when you least expect it. High temperatures can cook the electronics that control your machines, resulting in erroneous readings, trip-outs or fried circuit boards. Cooling the electrical cabinet can eliminate these problems, BUT HOW WILL YOU DO IT?.

by Fans

Opening the panel door and aiming a fan at the circuit boards is a bad idea.

- It is an OSHA violation that presents a shock hazard to personnel

- The fan blows hot, humid, dirty air at the electronics

- The cooling effect is minimal

- It is likely to fail again since the environment is still hot

by Heat Exchangers and Heat Pipes

These have serious limitations. On hot summer days when the temperatures of the room and inside the enclosure are about equal, there’s not enough difference for effective heat exchange.

- They fail when dust and dirt clog the filter

- The cooling capacity is limited due to ambient conditions

by Refrigerant Panel Air Conditioners

These coolers are prone to failure in dirty, industrial environments when dust and dirt clogs the filter.

- It takes almost a day to install

- Vibration from machinery causes refrigerant leaks and component failures

- Compressor life expectancy is typically 2.5 years of continuous operation

- It requires a floor drain for the condensation

- Thermostat control can decrease compressor life

- Average cost for replacing a bad compressor is $750

by EXAIR Cabinet Cooler

EXAIR has a complete line of Cabinet Cooler Systems to dependably cool and purge your electrical enclosures. They convert an ordinary supply of compressed air into clean, cold 20ºF (-7°C) air. They mount in minutes through an ordinary electrical knockout and have No Moving Parts to wear out. Compressed air filtration is provided that keeps water, oil and other contaminants out of the enclosure.

- There is no room air filter to clog

- An accurate electrical thermostat control minimizes compressed air use

- All Cabinet Coolers are UL Listed to US and Canadian safety standards

- They are the only compressed air powered coolers that are CE compliant

Here are some sample of Cabinet Cooler applications:

A Side Mount Kit is used when mounting on top of your cabinet is not an option or if space is tight.

Dual Cabinet Cooler Systems combat higher heat loads

NEMA 12 Cabinet Cooler Systems remove heat and prevent electronics from failure

Small NEMA 12 Cabinet Coolers Resist Heat and Dirt.

Small 316SS Cabinet Coolers with Digital Control Resist Heat and Corrosion.

The 316SS Cabinet Cooler for food and pharmaceutical services

EXAIR Cabinet Cooler keep working at full capacity after seven years of near constant operation, No Maintenance had been performed on the Cabinet Cooler System in that time (as none was necessary) even though the environment was quite dirty, it was still working perfectly!.

If you need more info, please Contact Us